Growing Blog

Keeping It Clean: How to Design and Build a Laminar Flow Hood

Keeping mold spores, bacteria, and other nastiness out of your mushroom spawn is a constant fight for the cultivator.

You could use a glove box with a pretty high rate of success, but anyone who wants to get serious about growing mushrooms needs to consider using a laminar flow bench.

Having a clean stream of air to work in is way more comfortable and much easier to use than an awkward glove box.

A properly constructed laminar flow bench can allow for ultra clean laboratory conditions even in a not so clean environment such as your kitchen or basement, greatly increasing chances of success for a home cultivator.

What is it?

The typical laminar flow cabinet consists of three parts:

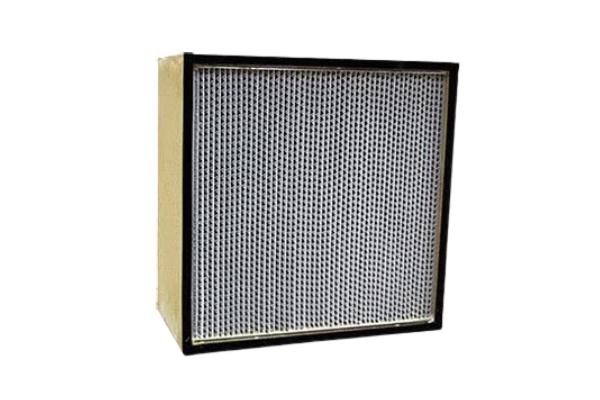

- A High Efficiency Particulate Air filter (HEPA filter) and pre-filter.

- A properly sized blower fan.

- A box to hold it all together and provide a plenum for laminar flow.

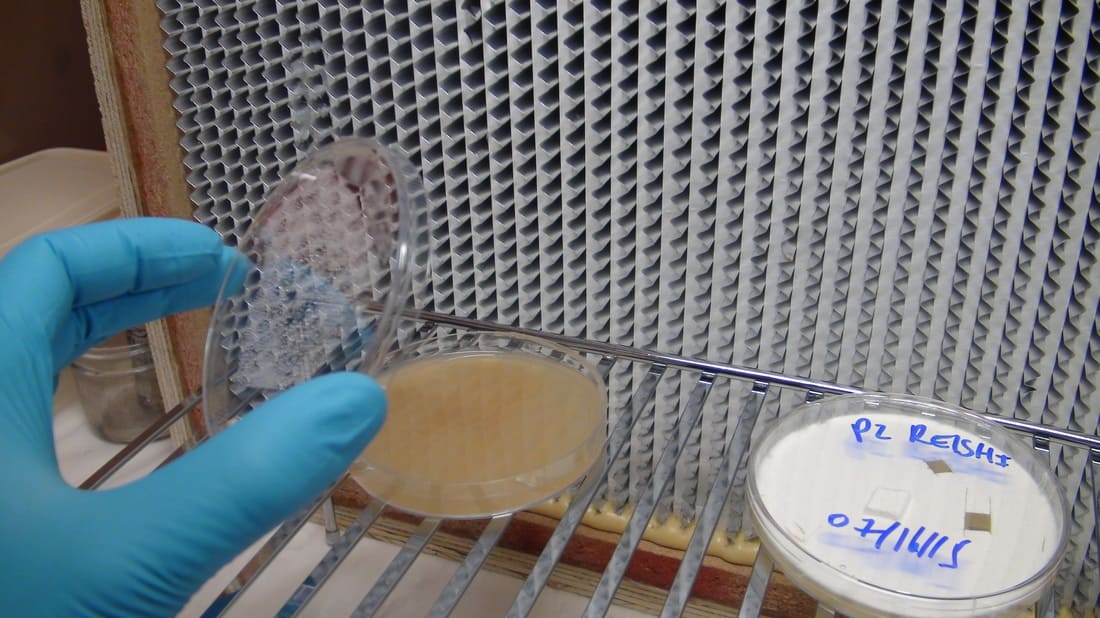

The idea is to provide a smooth and constant flow of clean air over a workbench. Working within this flow using proper techniques should allow for petri dishes and spawn jars to be open without risking mold spores or other contaminants getting in.

The end result is easier and more successful inoculations, grain to grain transfers and agar work.

Follow these three steps as a guide to building your flow hood:

STEP 1: Choose a filter

The main consideration when choosing a filter is size. A 12″ x 12″ filter may be okay for home cultivation, but the relatively small size makes it difficult when dealing with large spawn bags or multiple jars.

Bigger filters, however, require a more powerful and more expensive fan to push through the required amount of air. A good size filter for at home or small scale commercial cultivation is 12″x 24″ or 18″x 24″ or 24″ x 24″.

You want the filter to have an efficiency rating of at least 99.97 % at 0.3 microns. This means that the filter will stop 99.97% of the contaminants sized 0.3 microns or smaller, allowing for a high chance of success.

Another consideration when choosing a filter is the static pressure.

Most HEPA filters will have between 0.8″ and 1.0″ of static pressure (measured in inches of water). This is simply a measure of the amount of friction between the filter media and the air being pushed through the filter.

You will also want to add a pre-filter, which is cheaper and easier to replace than a HEPA and will stop big particles from clogging up your filter. It is generally installed at the intake of the blower fan. You can use cut-to-fit vent filters to customize the pre-filter to the size you need.

This pre-filter will have a static pressure of 0.1″ to 0.2″, making the total static pressure of the filter system somewhere between 1.0″ and 1.2″. This is actually quite a lot of static pressure and requires an adequately sized fan in order to provide a sufficient stream of clean air over your work area.

The information for both the efficiency and the static pressure of the filter should be provided by the manufacturer. You are unlikely to find this type of HEPA filter locally, however, there are many sources online, offering a number of different sizes.

Here is a good one from Amazon, a Novatek filter that measures 24″ x 24″. Or this 24″ x 24″, by Filtration Group is also good choice. If you want to build a smaller filter, you can choose to get a 12″ x 12″ HEPA filter, which may be adequate- albeit just barely- for small scale home cultivation.

NOTE: Make sure you get a proper deep seated filter, such as the ones listed above in order to get smooth laminar flow through the face of the filter. There are cheaper “HEPA” filters, such as the once available for home furnaces – but don’t get these. They will filter the air just fine, but will not produce laminar flow, and thus won’t work for your flow hood.

STEP 2: Size the fan

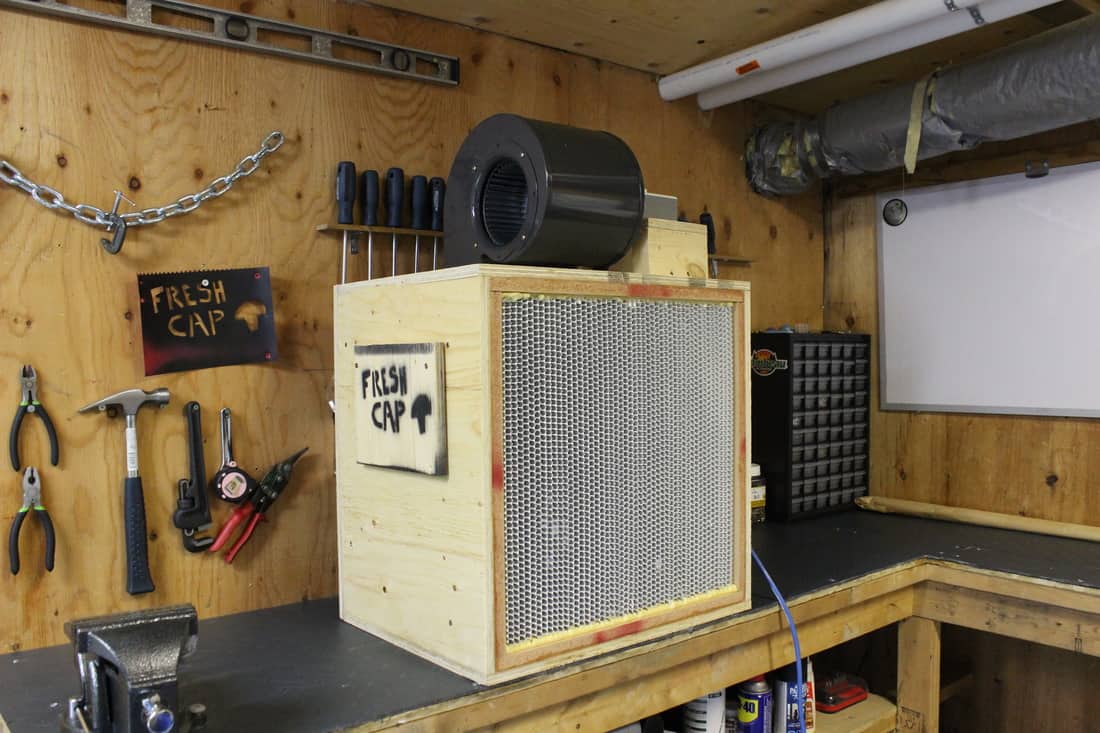

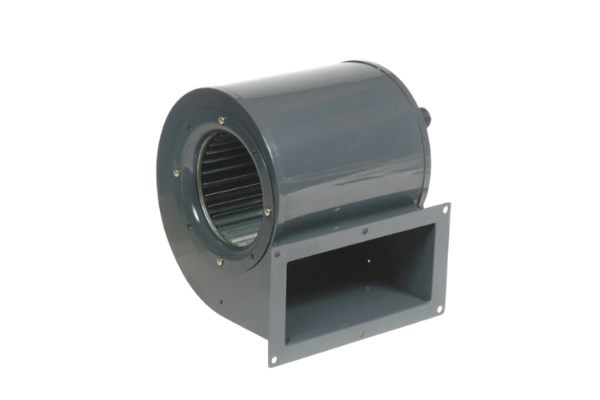

Laminar flow hoods typically use a squirrel cage type blower fan that is mounted on top of the hood.

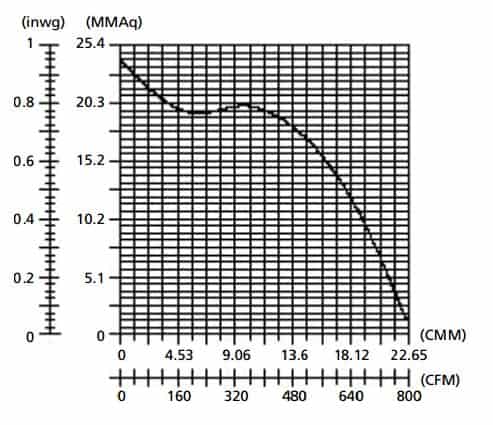

These fans are rated based on the volume of air that they produce at zero static pressure in cubic feet per minute (CFM). As the static pressure increases, the amount of air the fan can produce decreases.

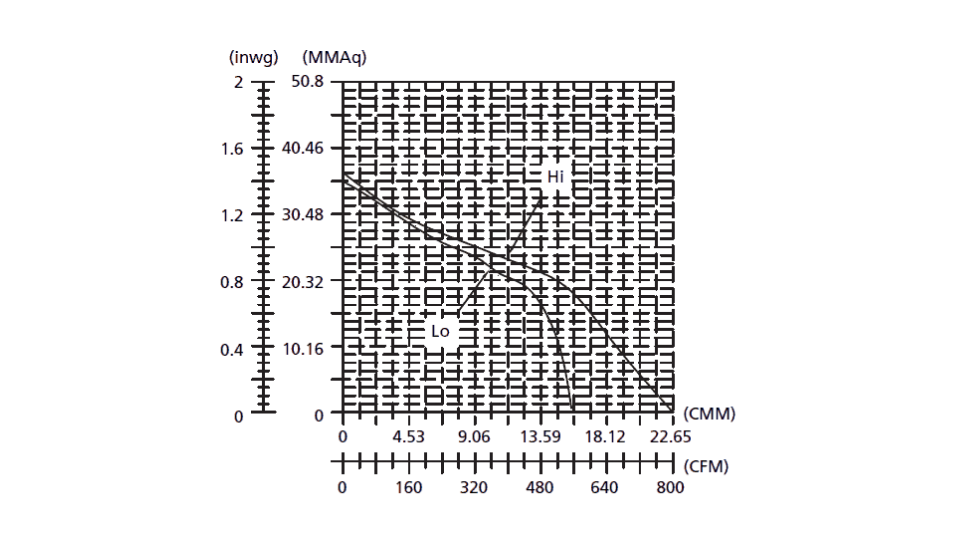

The volume of air that a particular fan can provide at a given static pressure can be shown in a “performance curve” which is usually provided by the manufacturer.

For mushroom cultivation, it is generally suggested that the stream of clean air should flow over the workbench at a speed of 100 feet per minute. This means that the volume of air flow required in CFM can be determined by multiplying the area of the filter by 100 ft/min.

For example, an 18″ x 24″ filter will have an area of : 1.5ft x 2.0ft = 3.0 sqft. Therefore, the volumetric flow rate of clean air required for mycological work is 3.0 sqft x 100 ft/ min = 300 cubic ft / min or 300 CFM.

This means we need to find a fan that can provide 300 CFM of air at the static pressure of the HEPA filter and pre-filter combined.

To continue the example, let’s say that the HEPA filter has a static pressure of 0.8″ and the pre-filter has a static pressure of 0.2″, giving a total static pressure of 1.0″. A typical performance curve for blower fans will look like this:

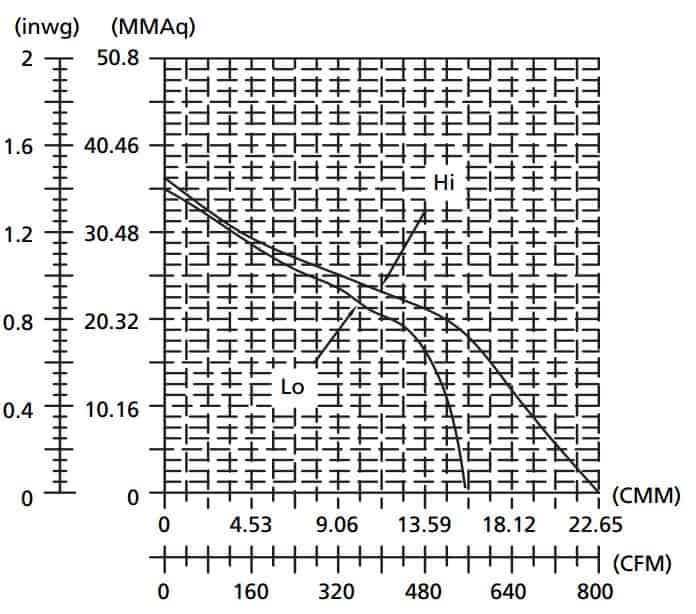

The fan in this example has two speeds, Lo and Hi, as shown in the chart.

We can find out the volumetric flow rate of the fan at our static pressure by looking at the curve. As you can see, at 1.0″ of static pressure, this fan should provide a flow rate of 320 CFM at the Hi setting.

This is called the working point, and since we required at least 300 CFM, the fan should be adequate.

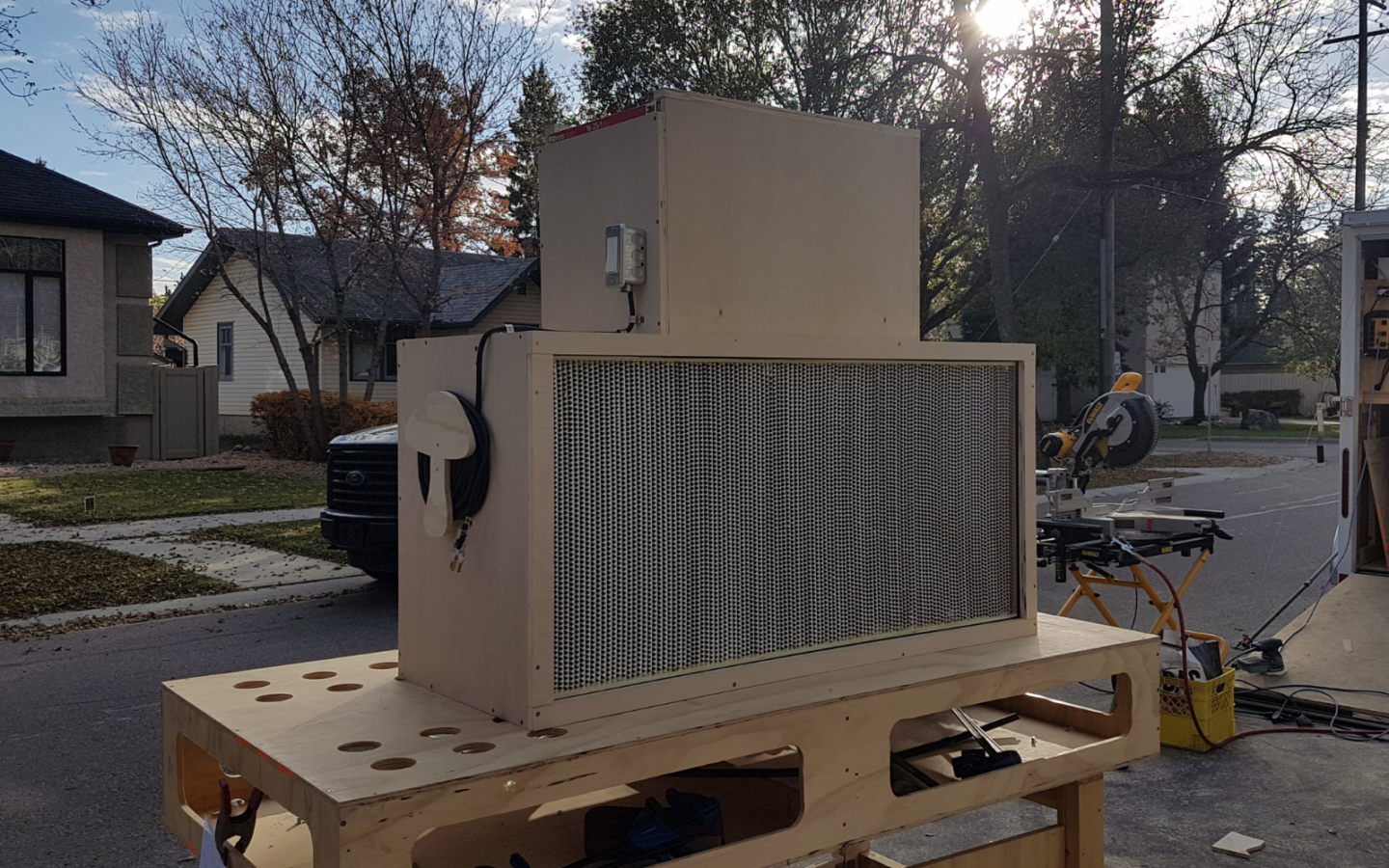

The fan I ended up using for my laminar flow hood was the Dayton 1TDT8, pictured here.

It has two speeds, so you can set your speed depending on the amount of resistance from your flow hood.

You can also use the higher speed to scrub the air of your lab quicker. You will need to wire in the fan using a switch. A simple light switch will work just fine.

Dayton also has a number of other fans that are reasonably priced and of good quality. Make sure you can also find the performance curve for your fan. There are a number of good choices at the end of this article.

You don’t want a fan that is too overpowered, but it’s better to have slightly more flow than not enough. Eventually, the resistance of the filter will increase as it gets dirtier, so having it slightly overpowered should be helpful.

If you look hard enough, you should be able to find a fan that will exactly match your filter. Again, these fans might be hard to find locally, but you should have no problem locating one online.

STEP 3: Putting it all together

The final step is to construct a box to hold it all together.

You want the box to have a reasonably sized plenum (enclosed area behind the filter), which acts to pressurize the air evenly over the back of the filter and produce laminar flow.

Laminar flow simply means that the stream of air is moving evenly and consistently across the filter.

You do not want turbulent flow, which will cause currents and unpredictable flows that can drag dirty air into your work area. You can check for laminar flow by holding a flame in front of your filter with the fan turned on.

The flame should be bent over at a relatively constant angle within the entire stream of air flow.

These hoods can be made relatively easy if you have the right tools. I was lucky enough to get help from my good friend Jeff over at The Home Stud. He’s got tons of great info on renovations, construction, and even some cool DIY hydroponics set-ups. Be sure to check it out!

The plenum should be 10-12 inches deep, not including the depth of your filter.

A good material for the box is finished plywood, at least 5/8″ thick and strong enough to withstand the vibrations caused by the fan. Use silicone to seal the edges, especially between the inside of the box and the filter.

You can build a separate box on top to house the fan with a pre-filter on the outside, or simply tape the pre-filter to the intake of the blower. There are many different ways to do this, so choose whatever works best for you.

Build This Same Hood

Wanna make your very own flow hood?

Check out the plans to build this exact hood below.

Pre-Built Flow Hoods

The cost of the fan, the filter and the plywood can actually get quite expensive.

Add in the time and tools required to put it all together and it often makes more sense to buy a pre-built laminar flow hood from a reputable supplier. Without a doubt, the absolute best choice when buying a flow hood is the wonderful folks at Fungi Perfecti.

They have a selection of pre-built flow hoods that should meet your needs at good prices. Check out the 24″ x 12″ Series I Laminar Flow Hood here.

Staying Clean

Try to keep dust and dirt off the face of your filter. It will be helpful to allow the flow hood to run for some time before use as it will clear the filter of any contaminants that landed on the outside and will scrub the air in the room.

Always use proper techniques like trying to keep your hands downstream of the cultures, plates or grain jars that you are opening. Keep rubbing alcohol nearby to wipe down anything that will be entering the clean stream of air. These sterile laboratory techniques will be covered in more depth in another post.

A properly built flow hood will greatly increase your success rate in reducing contamination in mushroom cultivation and is well worth the effort. If you don’t want to go through the trouble of making the hood, there are completed flow hoods available for purchase online, although they can be expensive and have high shipping costs. We hope to soon provide filters through our store.

Feel free to write questions or comments below.

Good luck with your flow hood!

=) great article

Hey Mikhail, I’m glad you found it valuable, thanks for reading!

I will be making a laminar flow bench this weekend, I like your design. When it comes to a laminar bench does it matter if the filter is 5 7/8″ deep or 12″ deep?… $100 difference not to mention the extra 6″ of room it takes up..

Hi Samuel! I think a 5-7/8″ filter will be just fine, as long as it meets the minimum criteria you want for filtering contaminants. Keep in mind also that a deeper seated filter, such as a 12″, will likely require a more powerful blower to maintain flow rate.

Hi. I realize I’m new here, but from what I know about flow rates, the overall depth should have no effect whatsoever assuming the power and opening sizes remain constant. (this from 30 yrs. of firefighting ventilation practice).

Not 100% certain but I think this has to do with the resistance encountered in the longer tubes in the laminar elements of the filter (Poiseuille’s Law). Flow rate is nearly inversely proportional to tube length. This can be easily demonstrated by using your mouth to blow air through a drinking straw that is an inch long and then compare it to one that is full length. You will encounter more resistance on the longer straw. These filters use corrugations which effectively mimic hundreds of straws to achieve laminar flow so I am guessing that is why. Thicker corrugated sections equate to better laminar flow at the cost of more resistance.

hi! i am curently looking to buy the right filter. the formula you use, it dosnt take the depth of the filter in count. so i will also stick to 150mm to be sure? as you mentiont in the reply, a 30mm filter would require a stronger blower. how would i calculate that?

Great article! I learned a lot from it today.

I’m trying to put a 24″ X 48″ flow hood, but can’t seem to find the right filter/fan combo. Would you be able to point me in the right direction?

Hi John! Thanks for reaching out. 24″ x 48″ would be rather large, I can’t think of any manufacturers that would make any one filter that size. I guess you could always build your hood using two 24″ x 24″ filters and 2 fans in tandem, just frame them in side by side. It’s possible that this kind of setup could have some negative effect on laminar flow, but I bet it would be negligible. Be sure to let us know how it works out!

Hi Tony! This is a great build. I’m putting together my list and hit a snag here. Aren’t these blueprints made for a 24″ x 48″ filter box? I found the Dayton 1TDU2 blower for a potential fit, but now confused about this post. If you’re still there, any help would be great!!

Fungi Perfecti sells 24×48 filters

Hi,

I really like your posts. They are very helpfull to me.

I have a question;

I am using ‘split air conditioners’ to mentain the temperatures.

But, I am unable to decrease the temperature of the room because of the lower voltage. The voltage is about 170 v. and the temperature of my growing room is about 21°C.

What do you suggest me to have lower temperature?

What kind of way should I follow?

Hi Mr.K! Thanks for the kind words! I am not that well versed on the voltage requirements for split air conditioners and would need to know a little bit more about you set up. I am guessing that your split A/C unit requires 220V? Depending on the size of your grow area, you could try using one of more “Portable Air Conditioners.” These are small individual units that can be placed anywhere in your grow area, and usually run on 110V. I have used one of these units before with pretty good success. Keep in mind though that a portable A/C unit is effectively a de-humidifier, and will dry out your grow room air while it’s running unless you increase the humidity some other way. You will have to provide for a way to collect the water that the portable A/C unit pulls from the air, or drain it off somewhere.

Good luck!

Hello;

Thank you for this wonderful page and i am sorry about my poor english. I want to make my diy laminar flow hood and found a hepa filter. Details of it: Class: H14 / Dimensions: 48″ x 24″ / Initial Pressure Drop: 250PA / Final Pressure Drop: 600PA / Max.Final Pressure Drop: 1000PA. Is it suitable for laminar hood, fungi culture? And if calculate correctly I need blower with capacity 800 cfm flow rate. Is it right? And I didn’t understand pressure calculation on your article. 7667036_orig.png provided by blower manufacturer? Or did you calculate it? Again I am so sorry for my poor english.

Hi Giovanni! Thanks for reaching out, your english seems fine to me!

I am guessing what you mean by “initial” pressure drop and “final” pressure drop is the different static pressure ratings of the filter as caused by the build up of contaminants over time. In other words, when the filter is clean, the pressure drop is 250Pa, but after time the filter gets dirty and so the pressure drop increases to 600Pa. 250Pa is a pretty standard initial pressure drop for HEPA filters, equivalent to about 1 inch of water, whereas 600Pa is quite high. This shows the importance of having a pre-filter, which will clean the air before it even reaches your HEPA, keeping the pressure drop lower for a longer period of time.

It is hard to say from your description whether or not it will be suitable, although it sounds likely. One other important detail to consider is the efficiency of the filter at a particular micron rating. 99.99% efficiency at 0.3 micron is usually a good bet.

As for the blower fan, you will need to look at the performance curve of the fan to see if it can actually deliver an appropriate flow rate at the static pressure of the filter (250Pa-600Pa). You want the air to be moving at 100 ft/min when it leaves your filter. The area of your filter is 8 sqft, so just as you calculated, you need a fan that provide at least 800 CFM- at the static pressure of the filter. If it can only provide 800CFM at zero static pressure then it will not be powerful enough. The performance curve in the article is shown as an example, and will be different for every blower. The manufacturer of the fan should be able to provide one for you that is specific to the fan.

Hope this helps!

Hi Tony!

Thanks for this article! I recently purchased a used Laminar Flow Hood Series I by Fungi Perfecti from a stranger. They claimed to have had little use with it. Currently cleaning the squirrel cage blow fan (it’s a Dayton 1TDT2). The front of the HEPA filter is a tad dusty, with a few scratches. And the rear of it is even dustier. Clearly they got some good use out of it! Being that the HEPA filter is paper material on both sides, do you have any recommendations for cleaning it up? I’ve gently run a vacuum across the front face, that did not seem to make a noticeable impact though. Any other suggestions? Is it a loss cause to attempt and get the dust/grime off the face and rear of this paper material HEPA filter? Thank you in advance!

Hi Reid!

Sounds like that filter has definitely had some use! The front of the filter can be cleaned just by turning it on and letting it run. As for the back side, other than trying to pull off some of the dust with a vaccuum or wiping it gently by hand there is not a whole bunch that you can do. If there is no pre-filter on the flow hood, the HEPA will naturally get clogged up over time. Have you tried using it yet? If you turn it on an hold a flame in front of it (you can use a bic lighter) you want to see that the flame is bent over, but doesn’t filcker too much or blow out. That would show laminar flow. You may still have many years of use out of the HEPA, but you may have to replace it.

Hi Tony, great info!

Have you worked with horizontal laminar flow(clean air comes from up the bench)? I must make one for my new room to save space on the bench, what do you think?

Best regards Yannis

Hi there!

No I haven’t worked with them personally, but as long as you get a area of clean laminar air flow in which to work in , you should be golden.

Hello, I am in the process of getting things in order to build a laminar flow hood. I found a place locally that sells squirrel cage blowers new and used.

I would like to build a flow hood that is 24″ x 2 4″ . I spoke to the man who sells blowers with a 450 cfm to 465 cfm with a 120 volt or a 220 volt. I have no idea how many volts I should consider so I said the larger 220 volt would do just fine. Used $50 to $125 new. How much importance is the voltage when buying a blower? What would you recommend I purchase of I want to build a bench with a filter size 24″ x 2 4″ or a smaller 1 2″ x 2 4″ ? I need all the help I can get from you before I make a purchase. Thanks

Hi Charlie!

The voltage is important. If you are going to get a 220V blower, you need to ensure that you can supply 220V power to it. I am not sure where you live, and I am not an electrician- but where I live, standard household power is 110V, ie. most outlets in your house will be 110V. Some things, like your clothes dryer and your electric stove will likely be 220V because of the higher power requirement for the heating elements. Unless you have an available 220V power source where you are going to put your hood, or you are going to get one installed, I would suggest getting 120V.

Also, you need to ensure that the blower can supply the proper flow rate at the static pressure of the filter. The flow rate your seller specifies might be the output at zero static pressure, which may not be enough.

As for size, it depends on what you are doing. If you are just doing grain transfers and inoculations in jars or working with agar, 12″x 24″ is likely enough. If you are inoculating a lot of spawn bags, you may want to consider the larger 24″ x 24″ which will offer you more room to work.

Hope this helps!

Hi Tony! I’m glad to have found your page- you’ve done a great job of breaking this process down and explaining it in a way that is easy to understand and replicate. I noticed you’ve said the HEPA filters should remove 99.99% of particulate at 0.3 microns, but the filters you’ve linked to are described as removing 99.97% at 0.3 microns. In your experience, does this issue impose a significant enough impact on contamination rates to be a cause for concern? I am having some difficulty finding a filter that fits all of the above criteria.

Hey Heather, thanks for reaching out! I appreciate the kind words. Thanks for pointing out this discrepancy- in my experience, the 99.97% filters are absolutely fine for small scale cultivation- they work tremendously well. The difference in contamination rate is so small that it would likely only make a difference if you were processing huge volumes of mushroom grow bags. The contamination rates are much more likely to be affected affected by improper sterile technique or incomplete sterilization than from a 0.03% difference in particulate efficiency. Hope that helps!

Hello friend i was able to locate a proper hepa h13 filter here with a intital pressure drop of 250pa and a final pressure drop of 600pa, can you help me sizing the fan/blower? how much cfm or m³/h i need before the filter to achieve 100-200 cfm after it? thank you!

Hi Mateus!

What size is the filter? 24″ x 24″?

Hey Tony…wonderful article, well sourced and comprehensive. I’ve done a lot of research on this subject but want to find a unit that is more manageable in size…say 12 X 12″ or 18 X 18.” The Stamets’ basic unit is too much for me to handle and quite expensive. I have zero construction skills and no tools. Have you ever seen anyone market a “kit” that one could just assemble? Even if someone made a kit that only included the basic box, wherein one could then purchase the filter, motor separately. I’m at the point now where Mr. Trich seems to be showing up more and more and I HATE using the glovebox.

Thanks in advance

Hey Micheal- Thanks for reaching out! I’m glad you enjoyed the article. I have not seen anything like a “kit” for making a flow hood- although it’s a great idea! You really only need a few tools, a drill, a circular saw, some glue and some plywood. Perhaps you can find someone locally that could assemble it for you? I do have some more pictures of the assembly, which I will get up on this article soon. I could send them to you of you like, just send me a note on the contact page.

Gloveboxes work great in a pinch- but are definitely limited! Good luck with it all.

Great tutorial and pictures! Have you looked into using a radiator fan which can provide 500-1800 CFM or high output computer fans that can produce 300 CFM? Seems like the latter might work with a 12″x12″ filter. I want to keep things as compact as possible.

Thanks! No I have not tried to use a radiator fan or computer fan. I would be surprised if the computer fans could produce enough air flow though something with as much resistance as a HEPA filter. A Radiator fan would probably do the trick, but I imagine it would be a little more difficult to build a housing. Worth a try though!

I have purchased a Koch biomax HEPA filter with the following dimensions- 24″x24″x11.5″ with the following specifications:

capacity- 1050 cfm

Initial pressure drop- 1.0″ w.g.

I am writing to inquire what capacity cfm shaded pole blower will be sufficient to supply the proper amount of laminar flow to perform my sterile work. Will this model be sufficient:

DAYTON 1TDR9 Blower, 463 cfm, 115V, 1.28A, 1600 rpm

Any assistance you provide will be tremendously appreciated. Thank you very much for your effort and for this excellent article. (:

Hi there! Thanks for reaching out! I think that the fan you have selected will be insufficient, as it won’t produce flow at 1.0″ wg. See the chart below for the 1TDR9 below:

With a 24″ x 24″ filter, you’ll need a fan that can produce 400 CFM @ 1.0″wg, plus pre-filter, and accounting for the filter getting dirtier over time. The Dayton 1TDU2 would definitely do it, but might be a little too high powered. The Dayton 1TDT8 would probably be a better bet, although it can’t quite produce the 400 CFM at the resistance of the filter, it comes close and should have the air moving at about 80 ft/min, which will likely be enough, and it is also easier to mount.

Hope that helps!

Tony

Thanks for your response, i found this model blower, will this one be more sufficient:

Dayton Model 1TDT8 Blower 797/549 CFM 2-speed, 1360 RPM 115V 60/50hz (5C508)

Definitely more sufficient. Like I said, it won’t be able to deliver the 100 ft/min speed of air, but it will be very close, and is likely the best option of the Dayton fans for the filter that you have.

What filter and fan are you using for your personal flow hood Tony? I trust that yours must perform well.

Hi Jon!

In my current home set-up, I am using a Dayton 1TDT8 (797 / 549 cfm) and a Astrocel 1 that is 21″ x 21″ by 6″ deep. The blower easily provides adequate flow at the low speed setting.

Where did you find such an odd size? I can’t seem to find anything but 24×24 for that filter.

Hey Jon,

I got it on ebay many moons ago. Still works like a champ! 24 x 24 would be a little bit nicer though in my opinion, but if you can find a 21 x 21 they are definitely adequate.

So would an Astrocell 1 that is 24×24 work with the Dayton 1TDT8 (797 / 549 cfm)? Or would I have to consider another blower?

Thank you so much for your input btw!

Hi Jon,

Likely yes, that would work, but you have to look at the resistance of the filter and compare it to the flow curve of the fan. Do you have the details for the Astrocel 1 (initial resistance?) It should be around 0.8-1.0 inmg. Here is the flow curve for the TDT8:

NIce article , i’am from Brazil and i am doing my laminar flow hood.

This article was very important to me. In Brazil, its more difficult find a exaust fan and a nice filter. Now, there is a doubt. There are 2 options:

1- Filter 5sqft , need 500cfm , and my exhaust fan Reaches perfect 494CFM in 1.0 static pressure of my filter. Velocity of air clean is 98,8 ft/min.

2- OR 4,275sqft x 100ft/min = 427CFM, my exhuast fan reaches 124ft/min.

What do you recommend? Can this increase in speed hinder the work?

I think that likely both would work. Keep in mind that the static pressure of the filter will increase as it ages. The safer bet would be to go with the one at a higher speed in my opinion, you could always put a pre-filter on it to decrease the airspeed / increase the static pressure.

Hope that helps!

Good night.

I’m from Brazil. Thank you for the answer.

Do you know if the exhausting fan must be on the box. Could i put the exhausting fan on the box but beaside.?

Sure, as long as you have the air flowing into the plenum at the right pressure it should work 😉

Hello! Thanks for the great article I was going back and forth on forums, this was actually very informative and it cleared a lot of questions. It was a clean cut and dry article. I do have a question though, Is this tough on the electric bill? I mean as far as I know I would only have the flow hood on for a maximum of up to an hour. Do you know any alternatives in fan that will save electricity? Thank you.

Hey Justin! Glad you got value from the article. I haven’t noticed it being all that tough on the electrical bill, but you should be able to calculate if you know how the amps and voltage of your fan. For my blower, the most it will pull is 3.0 Amps at 115 Volts- which if run for 1 hour is equal to 0.345 kWh. We pay about $0.04 per kWh, so running the fan for an hour should cost less than 2 cents.

Hey Tony! I have a 24″x24″x11.5″ HEPA filter (one of the same you linked above), and I am wondering if the Dayton 1TDT8 797/549 CFM is sufficient for that thickness of the filter. And also, is that blower a 110 or 220? Thank you!

Hey Shawn! It should be OK, but you need to know the static pressure of that filter to know for sure if it will be sufficient. My guess is yes, it will be good enough. That blower can be run on 110.

1160mm x 600mm x 50mm

Shane

HI Tony. I found a 18″ x 24″ x 5-7/8″ 99.97% HEPA filter with capacity of 420 cfm and initial pressure drop of 1.0″wg. Im wondering if the Dayton 1TDT8 797/549 CFM is sufficient for this filter.

Thank you!

Hey Luis! Yes it should. You need a fan that can produce 300CFM @ 1.0″ wg, looking at the chart for the Dayton 1TDT8, you should easily be able to achieve that.

Thanks Tony. Love your YouTube videos. Curious about the pre-filter. Is it mounted ahead of the fan, or just ahead of the HEPA filter? If the latter, then an inexpensive furnace filter the same dimensions as the HEPA should work well, I would think.

Hello Tony,

I think I bought a HEPA filter too big for this project hoping you can shed some light on whether or not I made a mistake.

I purchased a 24x24x11.5 99.97% HEPA filter with a capacity of 2000 CFM and initial pressure drop of 1.4″wg. Estimating an intake filter at around .2″wg, I believe I need a fan that will produce ~400cfm @ 1.6″ w.g.

The problem I’m having is that I’m not able to find any of these fan performance graphs and it’s turning out to be a little bit frustrating. I was wondering if you could help.

Hey Geoff,

Yes, your calculations at first glance seem to be correct. Any fan manufacturer should be able to supply you with that type of performance curve. Perhaps try contacting some manufacturers directly?

Hi Tony

Just planning to build the laminar flow hood using Micron Filter 64cm x 32cm x 15cm and appropriate barrel fan. I want to install it in the opening between two room so I can construct it to suck the air from the adjacent room or from the room into which the clean air will flow.

Based on your experience and understanding, would it of any benefit to have the air flowing from the other room. The work room/area will be quite small and I am planning to put a curtain to separate it from the stairs behind

Cheers, Zoran

I have done this before in a small lab and it works well! It also keeps the room under positive pressure, so that it protects the entrances from introducing contamination.

Tony,

When you say simply tape the pre-filter to the intake of the blower. What does that look like? From the photo of your set up, I am guessing you cut a square that matches the fan to blow air into the box. Is there a pre-filter between that cut square and the blower?

Thanks

Michael

You can really just tape in on the outside 🙂 I don’t have a picture right now, but whatever method you use to make sure air first passes through the pre-filter will work. What I used to do was bring in air from another room, and filter it before it came in. At the moment, I am transitioning set-ups and don’t even have a pre-filter on the blower. It still works fine, but over the long run will reduce the life of the main filter.

Hope that helps!

It appears from your photo, that you are inoculating the Petri dishes in front of the HEPA filter on a metal rack? No inoculating chamber? Something to share from the past…

I grew “Roooms” back in the 70’s and built a plywood inoculation chamber box, painted and sealed inside, two holes below a slanted glass window, with long rubber gloves attached to the box. A side door to place quart jars, agar pre sterilized and then, using sterile scalpel and twizers, sliced and diced the culture to the agar. BOOM! In a few days the Petri dishes were covered! Still with-in the chamber, I added the inoculum to approximately 1/4 c. of rye grains in quart jars that had been previously steam sterilized and a few more days the inside of the jars were totally covered in mycelium. This whole thing cost maybe $40.

I did not use any type of filter system. Do I have to have air flow? Did I miss something? Whew! Must of had too much coffee! Really tho, thank you for your great sharing of information. I want to get back into the medicinal properties of these GREAT healing Spirits!

Namaste.

Loren.

“Use silicon to seal the edges, especially between the inside of the box and the filter.” Could you give more detail on where to apply silicone between the filter and inside of the box? I can imagine it would be more difficult to replace the filter if the silicone was applied deeper inside the box instead of on the front where the seam between the two would be. I hope that makes sense. Thank you!

Hey Phin! I don’t really have a picture, but I just mean to apply silicon around the outside edges of the filter, inside the box. This prevents air from squeaking out the sides of the filter. It doesn’t doesn’t make it any harder to remove the filter when you need to change it. Hope that helps!

My filter is 24x18x5.8, (1″w.g.). I fully intend on using a prefilter so static pressure around 1.2″ total. Do i need to compensate for filter getting dirty over time,so instead of a blower that does 300cfm at 1.2″, maybe one that does 350-400cfm at 1.2″? Either way, the dayton 1tdt8 does not look like it can achieve even 300cfm at 1.2″ static. My question is, what is the next size up blower from the 1tdt8 that will put out around 350cfm at 1.2″ static pressure ? Thx in advance

Hi, Tony!

You say “deep seated” HEPA filter, otherwise no laminar flow will be produced.

I’ve checked at many filter manufacturers’ sites and they usually offer “deep pleated” and “mini-pleated” HEPAs, the deep being … well … deeper : >=18cm 😉 But yet many promote their mini-pleated series (usually around 8cm thick) as “laminar” while I’ve seen some deep ones promoted as “turbulent”. And they all say mini-pleated is a new technology, allowing for cheaper filters… Do you have any experience with these?

Thank you!

If they are “laminar” than they are probably good, I would say 8 cm is plenty deep. The ultimate test is to hold a flame in front of the filter and see if you can bend it without it getting blown out.

Can A blower from a central air unit work i definitely think it can provide enough flow its pretty big or is t much flow a bad thing?

It definitely can work, but it depends on the rating of the blower. Too much air can be a bad thing, but it is better than not enough flow. You can always restrict the fan with filters, but you might draw more power and burn it out.

Hi, I just purchased a HEPA filter and the only static pressure provided was 1.4”@250fpm. Do I calculate for this, but add a dimmer to fiddle with the speed when I finish building it?

Hey Jeremy, not sure in your exact situation, but you need to find a fan that can provide around 100 FPM at the static pressure of the filter. So it will depend on the CFM the fan can put out at that pressure, and the area of the filter. Hope that helps!

Amateur mycology has really ruined terminology this is not a laminar flow Hood it is a positive Airway that is HEPA filter which may work but it is not a laminar flow Hood. I worked in labs for the past 25 years and a laminar flow hood is a hood it’s an enclosure with positive airflow that’s HEPA filtered some of them drawdown the equal amount of air that is put in the hood so it doesn’t blow onto your body. But all of them are enclosures typically made from acrylic and aluminum channel

Hey Fred! You’re right, the term “Laminar Flow Hood” isn’t quite technically accurate, but most people in mycology use it as a synonym.

Hi

I have built a nice laminar flow hood using a filter of approx 60cm x 30cm that I aquired from ebay. The filter is new, also looks perfectly clean, but it was just sent in a simple cardboard box without any extra cover. Therefore I am a bit worried that it is probably already contaminated with some mold spores.

Any recommandations how to sterilaize resp. clean the filter? Tought about puting it into the kotchen oven for a while, but unfortunately it is to big.

Hey Tim!

This shouldn’t be a problem. If you build the hood and let it run for a while, all the contaminates will blow off the filter. Any new air coming through the filter should be clean. I have heard of some people spraying it down with alcohol, but in my experience this is not necessary. My first filter came the same way (even had rips in it!) and it was never an issue.

Happy growing!

Hey Tony!

This post was fascinating and it seemed to cover every aspect of the science behind laminar flow! I am just starting out and haven’t even attempted my own grow yet. Obviously this seems to be the most expensive part of the whole process when starting out or “up”ing your game in your lab, very similar to my first LED grow light when I started hydroponics. My question is that, am I led to believe that by using a laminar hood, my chances of contaminating a spawn is greatly reduced? Along side other preparatory measures like gloves, wiping down everything with rubbing alcohol and a sterile alcohol flame for syringes and blades, that you can be and feel somewhat carefree when enjoying your new hobby? Thanks for the help. The whole world of mycology is so fascinating and I am so grateful to come across this post!

Hey Josh! Really glad you liked the post… I actually have a new series of videos on this aswell- be sure to check out our YouTube channel- I describe the process of specing out the components and even building the hood. As for your question, having a Laminar Flow Hood does indeed greatly reduce the chances of contamination, providing a clean stream of air to work in. But keep in mind, it only really removes ONE vector of contamination- air. You can still have contaminates on your hands, syringes, blades ect… which need to be dealt with seperately. So a flow hood IN CONJUNCTION with sterile technique is the best way to go!

Thank you for this in depth description on the specs and details about how and why a flow hood works! It is a valuable asset to have much appreciated and almost all the materials are listed and linked which is invaluable in my opinion.

May someday the soil be valued more than gold!

Thank YOU for reading! Glad you found it valuable 🙂

Hi there Tony. I’m building a 24″ x 32″ laminar flow hood as my 24″ x 12″ Fungi Perfect Series I just isn’t big enough any more. I’m hoping that your plans will be helpful in the construction even though it for a different size. Please send me a copy.

Thanks,

James.

Sent 😉 Good luck with your new hood!

Hi Tony,

Thanks for the great article. I would like to know more about building my own flow hood.

Could you send me a copy of your build plans, please?

Sent 😉

Can I please get your plans for the 24 x 48 laminar flow hood?

Hey Lisa! Sure- just sign up in the box on this page and the plans will be automatically sent to you 🙂

Tony, thank you for sharing all this great info, I’m sure I will have questions, but for now thanks.

John

Nice write up. I will stick to Still air box’s for now, LOL. I’d love a flow hood but I see no reason to get or make one yet as my SAB let’s me to sterile agar work and g2g transfers and also printing caps for spores. Don’t get me wrong tho I’d love a flow hood!

Awesome, thanks for reading! And ya- if a SAB is working for you, then that’s definitely the way to go!

Hi Tony. I followed your YouTube channel and I have read most of what you’ve written here on your site. Fantastic and very informative. I have a question. Which blower do you use in you’re 24 x 48 flow hood? I ask because even the big blower you have linked does not provide enough volume at even 1in of water. In fact at 1 in It looks to be about 400. I really want to build this flow hood but need to find the appropriate sized blower. Thanks for all the time you put into answering our stupid questions. 🙄

Hey there! For the 24 x 48 I used the Dayton 1TDU2- works awesome!

Thanks so much. Parts are ordered. Have a tech question I hope you can answer. Using the above blower, what is the effective distance from the filter you can work contaminant free? I have limited space and plan on making the flowhood vertical instead of horizontal to save the 30″ of space behind the work station. However I don’t want to feel like I am back in a glovebox. I want some room above the bags.

Also your emails, are they the no-reply type? Or can they be replied to.

Best bet is to hold a lighter in front of the hood once it’s built and see what the range of laminar flow is. In general, the closer the better, but you can easily get 2 feet away, and be good (depending on the height of course). And yes, definitely feel free to reply to my emails, I read every one!

I had the same question, but I’m slightly confused. The static pressure of the 5-7/8″depth filter is still 1.0″ IN.W.G.. This is the same as the 12″ AstroCel 1. Doesn’t this mean it will essentially require the same blower?

Thanks for this amazing resource of info by the way!

I would love to know where you got your 24 x 48 HEPA I can’t find anywhere online so far……..thank you!! These are wonder plans! Bless you guys

Hey Chelsea! This one was from a place in Edmonton (The Filter Shop) but they are made by AAF Flanders- might have to be custom ordered. Send me an email if you want and I can give you a contact.

Thanks!

Tony you bloody champion! Thanks for existing, dude 🙂

Would it be at all necessary or beneficial to have walls and a roof on the bench space if you know what i mean? like have the work area enclosed or separated from the space directly above and adjacent to the filter face? or am I just overthinking now?

Hey Jeremy! You can never overthink, but having side walls and a roof is not at all necessary, and actual makes the mycological work quite cumbersome. Better without 🙂

Hi Tony,

Very interesting article.

I plan to build a cabinet where two people can work side by side.

The size would be 2.5 meters wide (sorry metric system).

Should I use one or two blowers?

How about the noise, can I use a noise insulation where the fans are placed?

I want to start a mycelium production here in Namibia, but at a low cost investment for starter.

Later (if necessary) I might go to a more professional system.

Hello Tony, thank you for the tutorial.

I made my calculations, I looks like I need a fan that can perform up to 800CFM, I JUST. OUGHT MY Dayton, but how many CFM has to come “out” of the filter? I didn’t get that part. I’m having scarce 80 CFM after the filtration…

I forgot to mention that my filters are 10 1/2” thick. I don’t know if that influences the results (2x 24x24x10 1/2”).

Hi Tony,

I built a 24″ x 48″ flow hood using your instructions and the same blower and filter. It was a fun project and I’m eager to put it to use! A quick question: how strong should the air flow be coming out of the filter? I was surprised at how little there was. With the filter out it blows like a hurricane. I know the filter is a major block for the air, but wanted to confirm (for my own piece of mind) that little air flow was expected. If I hold a piece of printer paper up to the middle and turn it on, the paper blows up about 4 inches. Thanks for your design and time!

Jeff

Hey Jeff! Yes, you shouldn’t expect a large force of air, barely noticeable when you are working. A good way to check it to hold a lighter or small flame in the air stream. It should bend over, but not blow out. Hope that helps!

Perfect test! Thank you for the quick response! 🙂

Who want to sell a 24×24 flow hood

Contact Aerofil International and they’ll sell you one. Alibaba can be another option.